Some of the features of our Solar Poultry Incubator are mentioned below.

Reliable, Versatile Solar Poultry Incubator

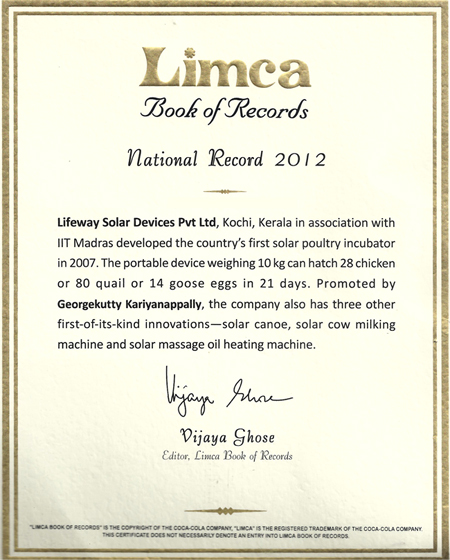

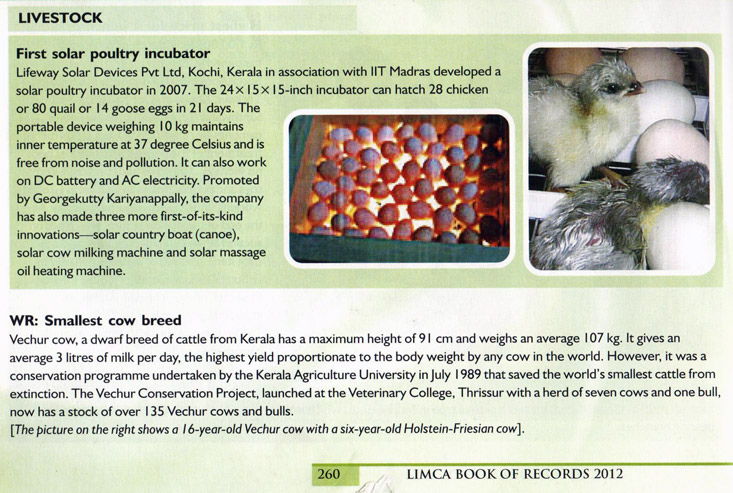

This semi-Automatic unit is capable of hatching 100 Quail, 40 Chicks or 25 Goose eggs. Supplied with fully automatic heat control and excellent thermal properties of the fiber glass cabinet ensure the least possible conditions for egg incubation particularly in rural villages. This incubator is developed exclusively for unemployed woman living in rural India to find themselves a self employment venture to support their families. This project has been approved by IIT Madras, Chennai and financed by L-Ramp. Now we are negotiating with various NGOs to take this product and impart training to women folks to use this Solar Poultry incubator where there is no electricity to hatch eggs.

Fighter Chicken cost from Rs.8000.00 to Rs.25000.00

Fighter Chicken cost from Rs.8000.00 to Rs.25000.00

Temperature Control

Precise and consistent control of temperature is essential for good hatching results. The fiber glass double skinned box with puff insulation further improving temperature stability and operational efficiency. Adjustment to temperature can be made by turning a nob. An indicator light shows the status of the control - whether the unit is warming up, stable or cool. The electronic proportional thermostat is well protected against power variation and also a battery is provided for power stability. A 12V/ 40 watt Solar Photovoltaic panel is connected to the battery with charge controller hence 24 hour supply is assured.

Egg Turning

This can be done manually by turning each egg 4 or 5 times in a day. There are no internal Electrical moving mechanism associated with the egg turning. So nothing to trap or injure emerging chicks.

Humidity and Ventilation

A computer grade fan will provide fresh air flow throughout the incubator. Humidity is provided manually by water bowl kept outside the incubator which is connected to a perforated PVC piping system.

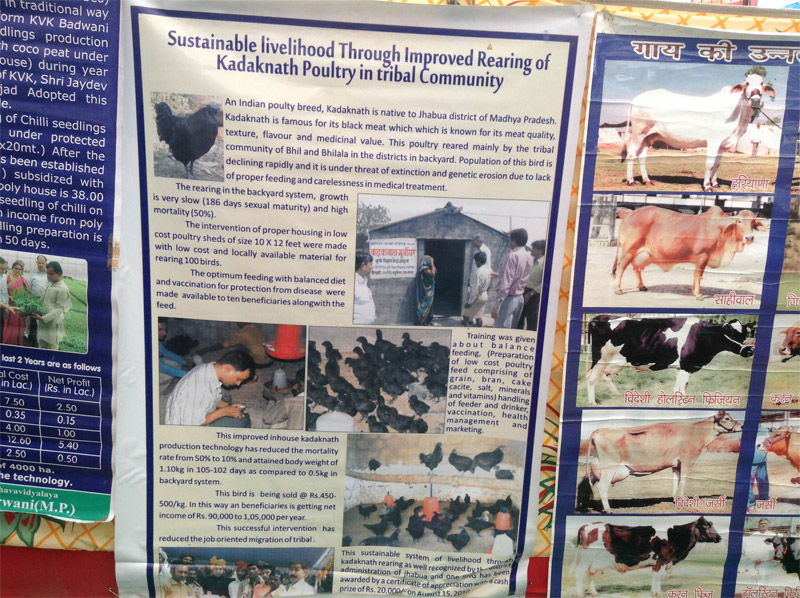

Distribution of incubators among villagers in Jhabua, MP, India.

Solar poultry incubators are distributed among villagers in Jhabua Dist. MP. On 13th July. Next batch on 22nd July 2014 under Rural innovation fund from NABARD, Bhopal division....

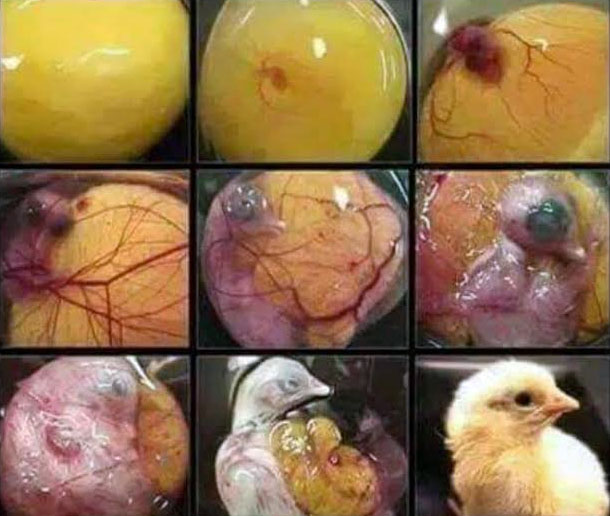

The growth of a egg into a Chick in 21 days

Various Solar Poultry Incubator supported Back Yard Poultry farming executed by Hazaribagh Krishi Vigyan Kendra and also in Deoghar and Godda and Ranchi under KVK scheme financially supported by NABARD. Training and installation conducted on 13th to 21st March 2016.

We are exporting Solar poultry incubators to Zimbabwe as part of United Nation's African Poverty Eradication Program. Life way Solar joining hands with one of the UN agency in Harare to install and create Awareness about solar incubator and Back yard poultry farming to create employment for unemployed women in Africa.

Solar Poultry Incubator

We are in the Solar Energy business and Poultry farming since 19 years in India. Exporting Solar Incubators to Nigeria, Afganistan, Nepal and particularly to Mr. Richard, RICALIS Enterprises Pvt Ltd, DBA Richards Agricultural Group, PO Box. CY510, Causeway, Harare Zimbabwe. We have sent Incubators to them as part of our United Nations project.

Solar Energy becoming an integral part of our life. From the beginning of this universe it was there however now only we have realized its potential and various applications in our day today life. I got an opportunity to develop an innovative product SOLAR POULTRY INCUBATOR with the technical and financial support from IIT Madras in 2007 and now it is mentioned in 2012 Limca Book of records too. This Fully Automatic unit is capable of hatching Eggs of Quail, Chicken, Turkey, Goose etc. Supplied with fully automatic heat control system with an excellent thermal properties of the fiber cabinet ensure the best possible conditions for egg incubation particularly in rural villages.

This incubator is developed exclusively for unemployed woman living in rural India to find and create themselves a self employment venture to support their families. This project has been approved by IIT Madras, Chennai, India and financed by L-Ramp. Now we are doing Back yard Poultry farming with various NGOs and impart training for women folks to hatch eggs in Solar Poultry incubators in those villages where there is no electricity connection from Grid or with frequent power cuts.

We have developed 200 Eggs Capacity Solar Poultry Incubators to 500 Eggs Capacity Incubators so far. We are the pioneers in Manufacturing Solar Poultry Incubators in India. At present we are running projects in Madhya Pradesh, Gujarat, Andhra Pradesh etc. This is a fully automatic System without grid power or Generator it can work and we are exporting it to various Countries.

We are also Renting out poultry incubators on monthly basis. For one hatch we charge Rs.10.00 per Egg. We are hatching Kadakkanath and fancy Chicks in our office for growers. Those who bring eggs will be kept in our "In house hatchery" and give them chicks after 21 days.

Technical Specifications

- Power – 24V/175 watt , DC System.

- Vega Solar Photovoltaic Module – 24V/200 Wp - Exide battery – 12 V/1 00 Ah – 2 nos

- Phocos Charge Controller – 24V/20 Amp - 16mm Core Copper Cable

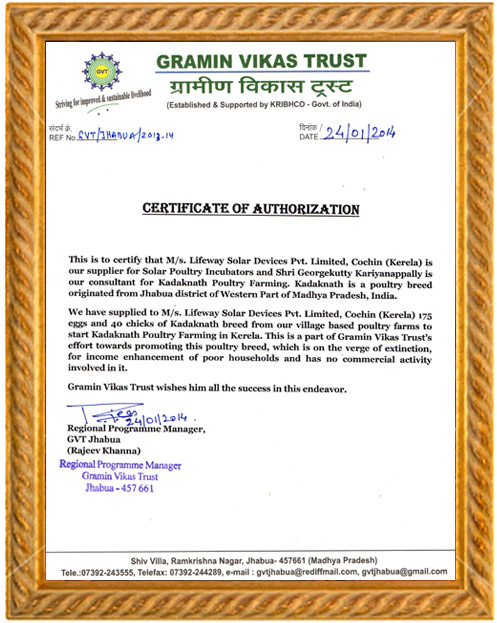

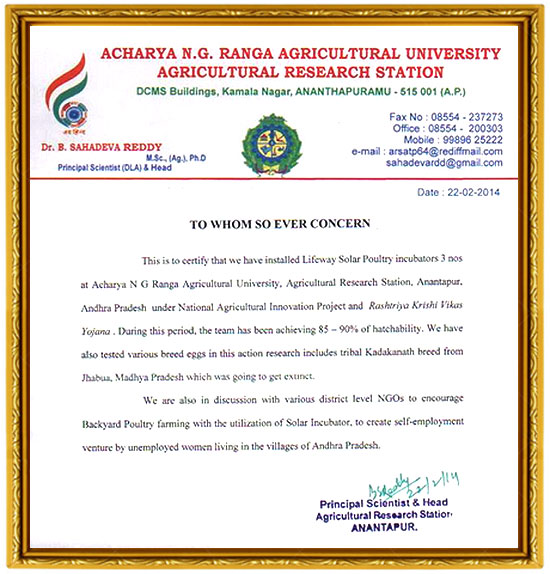

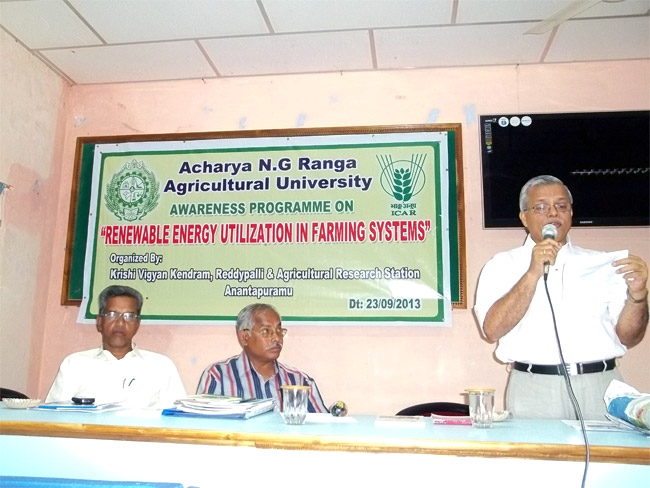

We are associated with Krishi Vigyan Kendras in 12 Indian states. Conducting projects in Jhabua, Dhar, Burhanpur in Madhya Pradesh, Ranchi, Hazaribag, Godda in Jharkhand, N G Ranga Agri. University in Ananthapur,Andhra Pradesh, Jayasankar Agri. University in Hyderabad,Meghalaya state council for technology and environment etc..etc...

We have started Back yard poultry farming with a vision to create employment for the unemployed illiterate women living in rural India. This is truly a process of EMPOWERING WOMEN especially for those who are living in rural villages and where there is no electricity or sufficient rain fall to do cultivation in their farm land...... We says, When there is no RAIN.... there is SUN. So we teach them to Harness sun shine and produce electricity and run Solar Poultry Incubators "A self employment venture by unemployed women".

We are also supporting to Kadakkanath Medicinal chicken originated from Jhabua, Madhya Pradesh. Its 1 KG Flesh cost Rs.1000.00 and Egg cost Rs. 50.00 each. Its a profitable farming and a good service to the society. This Kadakkanath Chicken flesh is good for Heart and Asthma patients.

There are certain villages in India having Self Help Groups doing Backyard poultry farming in a big way. Each group consisting of ten ladies. They can avail up to 30 Lakhs bank loan with minimum interest without collateral to start the project.

Lifeway Solar Devices Pvt. Ltd at Cochin, Kerala is the manufacturer of Solar Poultry incubators and also developer of this project which will give technical support to the buyers. Similar Projects are running in Jhabua under the stewardship of Grameen Vikas Trust in Jhabua and also in Ananthapur under KVK and Ranga Agricultural University in Ananthapur.

We are inviting NGOs and like minded Farmers interested to do Back yard poultry farming in your state may contact us through E mail or call us.

-

- 100% silent & pollution free.

- Creating employment for poor women living in rural India.

- Portable & Less (20/60 watt) energy consumption.

- Simple operation & training imparted.

- Works on three power options Solar, Battery, Grid Power.

- One year warranty.

- An excellent product for Kudumbashree – Self Help Groups to start self employment venture with bank loan.

- 30% capital subsidy from Ministry of New And Renewable Energy through NABARD.

- 5% interest loan from Syndicate , Canara Bank.

- Possible Kerala Govt. Subsidies.

Related Pictures, Videos, Certificates

Frequently asked questions.

-

Why should Poultry farmers go for solar incubators?

The advantages of solar incubator is when comparing with conventional one, it will work in three power options. Grid, Battery and Solar . The additional benefit is it will conserve energy, an Eco friendly product and also easy to use.

Energy Conservation

The solar incubator can save up to 50% electricity , so that the hatching expenses will be less.Environmental protection

According to the calculation, during the ten years using, each solar incubator will reduce the coal discharge into the atmosphere of 12 tons of carbon dioxide, 656 tons of carbon monoxide, 520 tons of dust, 162 tons of sulfur dioxide, 350 tons of hydrogen nitrogen compounds, this is not a small number, so the use of solar energy incubator is green environmental protection an effective measures.Safety

At present Lifeway Solar design of solar incubator machine in 12 V as well as in 220V , you can make arbitrary choice before ordering our incubator. The operation is simple ,comfortable, Safe and reliable. -

What kind of environment is suitable for solar incubator?

This is a Solar Energy Powered product designed for villagers. Millions of women living in our Villages are without grid power. We are mainly focusing on this sector. Creating employment opportunity for them " A self employment Venture by unemployed women." 40% of the Indian population is without power supply. Most of the grid powered areas are also not having stabilized power for 24 hours. Power cut for 5 to 12 hours are even in cities.So they have to depend either on Diesel Generators or on Inverters. -

Is it too complicated to install the solar incubator in Villages?

The installation of solar incubator is very simple, we have set all applications on components before dispatch.Cosumers need to connect it to grid and solar panels. Most of the time our installation team will assist you in installations in your area or it can be communicated through mobile phones. -

Is it possible for us to use this Solar Energy to light up our house when we are not using Solar Incubator?

Yes, It is possible but only one 10 Watt CFL which is working on DC power can be used for 7 Hours. You should install the Solar Module facing to south in 10 Degree Angle to harness sun rays from 10 AM to 4 PM. But do not light lamp CFL when Solar Incubator is working. -

What is the lifetime of the solar Poultry incubator? Is it breakdown frequently?

No. It will not, This design is for minimum above 10 years life. However it all depends how you are going to use it. . It is depend on circuit component aging or short circuit damaging due to misuse.. When anything goes wrong call our Engineers or replace the damaged parts by local technicians. -

What is the difference between normal incubator and the solar incubator?

The normal incubator which is available from local market is maximum power consuming product. You need to have an inverter or Generator if power fails. Otherwise the entire eggs kept for hatching will gets damaged. Where as in Solar poultry Incubator there will not be any power shortage or breakdown. Also there will be no recurring expenditure to run the Incubator. -

Is it Possible for us to use this solar panels for some other purpose?

Yes, The energy harnessed by solar panels can be used for lighting your house also to use television and computer. -

The chicks in my machine are fully formed, some pipped, but did not hatch. (late death) What went wrong?

This common problem can be caused by many factors. The most frequent cause is incorrect humidity – usually too high. -

The chicks in my machine are only part formed (very early death) What went wrong?

Again number of possible causes: turning failure, bacterial infection in incubator, temperature fluctuations, power failure or problems with parent stock (e.g. in-breeding, poor nutrition). -

The power has gone off. How long will the eggs be OK for?

Generally for a period of up to an hour. If the unit is well insulated and the temperature doesn’t drop too much this could be longer. Our machine can keep about 3 to 4hrs. -

How often should eggs be turned?

It is recommended that poultry, game and waterfowl eggs are turned a minimum of twice a day – ideally more often. Automatic turning is often hourly. Some species (parrots and birds of prey) need tuning at least every hour. -

How long can I leave the chick in the incubator after they have hatched ?

Leave the chicks in the incubator until their down is dry – usually about 24 hours. They will not require food or drink in that time. -

Should I spray the eggs during incubation or when they are due to hatch ?

Spraying only increases humidity for a very short time and will not ‘soften’ the egg shell. Spraying eggs can also transmit or spread infection and is therefore not recommended. The main effect it has on the egg is to cool it as the water evaporates. There is some evidence that periodic cooling can improve hatch results but this should be achieved in other ways (e.g. leave the lid open for half an hour per day). -

When I set the eggs which way up should they be?

It is essential that eggs are set so that the round end upwards or they are on their sides. -

I am confused about the correct temperature for my eggs. I have been told different temperatures by different people. How can I be sure which is correct?

Always refer to the manufacturer’s instructions as different types of incubators may require different settings. -

When should I stop the turning ?

Turning should be stopped and the machine set level 2-3 days before the eggs are due to hatch. -

What is the correct humidity level for incubation.

Generally for poultry it is between 60-70% and last 3 days 70-80%.

Click here

Click here